Overview of pallet racking and its uses

Pallet racking is a type of warehouse storage system that helps store and organize items. It uses heavy-duty pallets or skids, which can be moved around the warehouse via forklifts or other lifting equipment. This type of racking is a very popular option for warehouses because it allows them to maximize their storage space and makes it easier to access goods and materials. Pallet racking is also used in retail, manufacturing, distribution, logistics, and other industries. The main purpose is to make sure goods are organized, safely stored away, and easily accessible when needed. Another purpose of pallet racking is to avoid the much larger costs of adding additional square footage to your warehouse or plant or having to move to a larger facility. Adding storage allows you to maximize your capacity and avoid larger capital expenses.

Common Applications for Pallet Racking Systems

Pallet racking systems have many uses in a variety of industries, including retail, warehousing, distribution, logistics, manufacturing, and more. In the retail sector, they are used to store inventory and goods in an organized manner. In a warehouse setting, racking systems makes it easier to store and access items quickly. It also helps maximize available storage space. Distribution centers use pallet racking to help streamline their order fulfillment operations. Logistics companies rely on efficient material storage systems so they can manage they goods they are transporting safely and efficiently. Finally, manufacturers use the system for storing parts or components that are used in production processes.

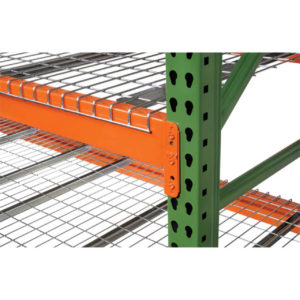

Understanding Different Design Types and Specifications

Pallet storage racking comes in a variety of types and designs, each type offering benefits to specific applications. For example, drive-in pallet rack systems are designed for high-density, deep storage requirements and provide fast access to stocked products. Selective pallet racks feature adjustable beams that can be used to store different size products in an organized fashion. One provider of standard teardrop pallet racking is Husky. Pushback systems are ideal for saving space since they require minimal aisle widths, but at the same time provide easy access to goods stored within. Finally, cantilever racks provide stable storage for non-palletized or long items like pipes or timber. Knowing which design type and specifications best suit your application is key to ensuring efficient operations.

Factors to Consider When Purchasing

When purchasing a pallet racking system, there are several factors to consider. First, assess your storage needs and make sure the system you choose can accommodate them. Second, think about the type of product being stored and select a system that is designed to handle its size, shape, and weight. Third, consider the environment in which it will be stored and specify racks with the appropriate finishes or coatings to protect against moisture or corrosion. Fourth, weigh up the installation cost with potential savings on space utilization and selectivity. Finally, look for safety features such as rack guards and end-of-aisle netting for added protection.

Benefits of Opting for Used Materials

Opting for used pallet racking systems can be a cost-effective solution, providing reliable storage in many situations. Used systems can be especially beneficial when you need to expand existing storage capabilities quickly and on a budget. Additionally, it can be easier to install a used systems compared to new ones since they may have been designed to fit into preexisting spaces or with existing anchoring methods. Used racks may also come with additional components such as rack guards that provide additional protection against impacts and falls. All of these factors make used pallet racking systems an economical and sensible choice when the budget is tight but quality storage is still essential.

Potential Problems to Consider Before Purchasing a Used Pallet Racking System

Purchasing a used pallet racking system can be a great way to save money, but there are some potential problems to consider before investing. First, inspect the system for wear and tear that may prevent it from functioning properly or safely. Most of the time, an inspection of the material is not possible, so this can be a huge risk. Second, check for compatibility with existing systems and make sure that any additional components such as end-of-aisle netting will fit in their intended spaces. Third, evaluate the installation process and determine whether you need to hire an expert for assembly. Finally, review any warranty information on the product to make sure it will cover any potential damage during transit or installation. Most racking suppliers will not provide any warranties or certify any weight capacities for used materials so this risk falls on the buyer of the materials, and should be taken into account when considering New vs Used pallet racking. Taking into account these issues can help ensure your used pallet racking system meets all of your needs.

Helpful Tips for Setting Up and Installing Material Handling Storage Systems

Setting up and installing pallet racking systems can be a daunting task, but with the right preparation and knowledge, it doesn’t have to be. Knowing which design type best suits your application is key to ensuring efficient operations, as well as understanding the various factors that go into purchasing a pallet racking system. Additionally, opting for used pallet racks can be an economical choice if you are working with limited funds. However, there are potential problems to consider before investing in a used pallet racking system such as wear and tear or compatibility issues. With these helpful tips in mind, setting up and installing pallet racks can become much simpler!

Do you have questions or want help selecting the best pallet racking solution?

Want help managing the selection, design, and installation of your pallet racking system? Purdy Company can save you time and energy by designing, purchasing, and installing pallet racking for you. You don’t need to worry about compatibility issues with existing systems or wear and tear on used pallets; their experts will handle it all for you. Our experienced professionals are knowledgeable in the latest pallet racks technologies and can provide helpful advice to make sure your needs are met. Get a comprehensive design that meets all of your storage needs without blowing through your budget. Enjoy peace of mind knowing our team is dedicated to safety first when handling pallet racking installation.

Purdy Company is the preferred supplier and installer of material handling and storage systems.

Purdy Company, founded in 1950, is the leading distributor and supplier of pallet racking in Ohio. Purdy Company is a leader in the design, procurement, and installation of pallet racking, wire partitions, lockers, mezzanines, shelving, and storage units. We have 3 install crews employed directly by Purdy to get the job done quickly, safely, and correctly. We have worked with every style and type of pallet racking and run into every issue on the job site. No two jobs are the same, and our vast experience allows us to meet your project schedule, quality, and budget.

Fill out the form below, or send an email to sales@purdyco.com and one of our team members will connect with you right away to meet your project deliverables.

Leave A Comment